According to the World Steel Association, there are more than 3,500 different steel grades, each of which has unique physical and chemical properties. This broad variety makes steel suitable for a wide range of applications.

Hot-rolled steel is one of the most frequently used types of steel; its excellent formability enables it to be manufactured into bars, sheets, tubes, and various other components. It is available in numerous grades, which find use in various applications.

Overview of Hot-Rolled Steel

Hot-rolled steel is carbon steel that has been heated to above its recrystallization point (typically at or above 1,700° F), flattened to the desired size and thickness by high-speed rollers, and worked into the necessary form (e.g., bar, plate, sheet). It can be low-carbon (containing up to 0.3% carbon), medium-carbon (containing 0.3–0.6% carbon), or high-carbon (containing more than 0.6% carbon). The processed material exhibits excellent mechanical properties at a lower cost than cold-rolled steel, which makes it an appropriate choice for many applications, including construction, railroad tracks, and sheet metal. However, since the process can cause scaled surface textures and/or material shrinkage, the material is best suited for applications that do not have tight tolerances or strict surface finishing requirements.

What Is the Steel Hot Rolling Process?

The process of making hot-rolled steel is as follows:

- Heating the steel to above its optimal rolling temperature

- Forming and rolling the steel into a large rectangular piece

- Feeding the piece through a series of roll mills to form and stretch it into a thin strip

- Water cooling the strip at the rate needed to achieve the desired metallurgical properties

- Winding it into a coil (if needed)

Common Hot-Rolled Steel Grades

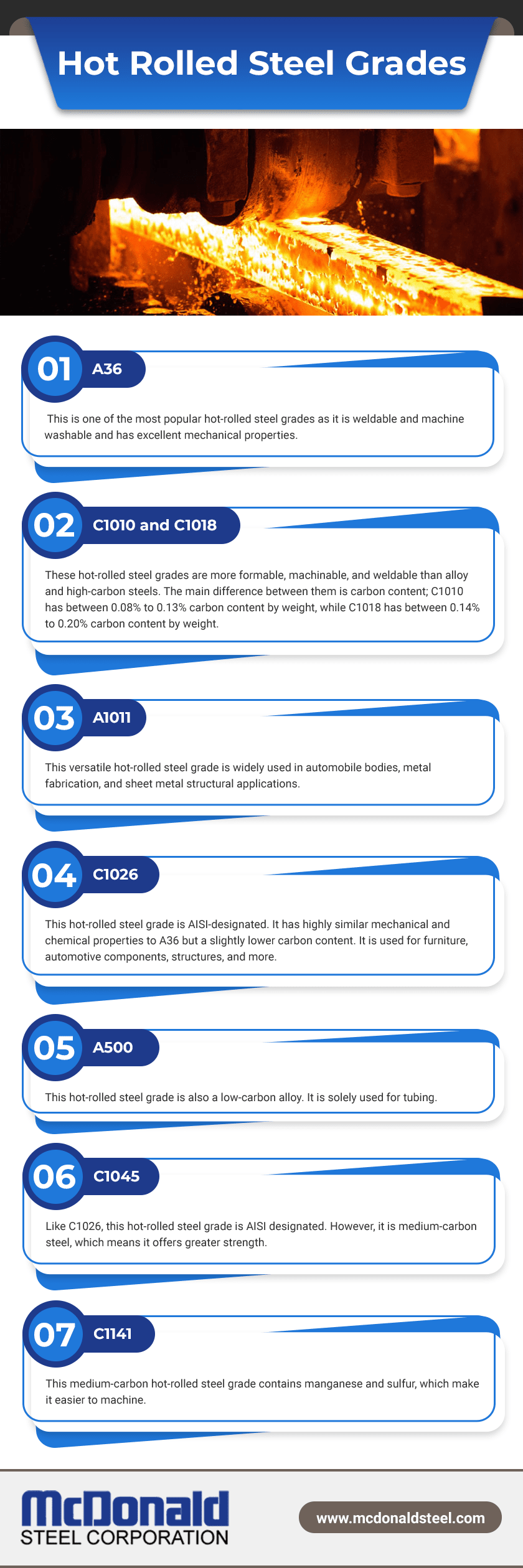

Hot-rolled steel is available in many grades or standards set by the Society of Automotive Engineers (SAE) or the American Society for Testing and Materials (ASTM). Some of the most widely used are:

- A36: This is one of the most popular hot-rolled steel grades as it is weldable and machine washable and has excellent mechanical properties.

- C1010 and C1018: These hot-rolled steel grades are more formable, machinable, and weldable than alloy and high-carbon steels. The main difference between them is carbon content; C1010 has between 0.08% to 0.13% carbon content by weight, while C1018 has between 0.14% to 0.20% carbon content by weight.

- A1011: This versatile hot-rolled steel grade is widely used in automobile bodies, metal fabrication, and sheet metal structural applications.

- C1026: This hot-rolled steel grade is AISI-designated. It has highly similar mechanical and chemical properties to A36 but a slightly lower carbon content. It is used for furniture, automotive components, structures, and more.

- A500: This hot-rolled steel grade is also a low-carbon alloy. It is solely used for tubing.

- C1045: Like C1026, this hot-rolled steel grade is AISI designated. However, it is medium-carbon steel, which means it offers greater strength.

- C1141: This medium-carbon hot-rolled steel grade contains manganese and sulfur, which make it easier to machine.

Learn More About Hot-Rolled Steel From McDonald Steel

Want to learn more about hot-rolled steel? Ask the experts at McDonald Steel. We are tooled to roll over 500 symmetrical and asymmetrical hot-rolled steel shapes. Our products find application in a diverse range of markets, where they serve as ideal alternatives to forged, cast, extruded, cold drawn, and machined steel components. For additional information on hot-rolled steel and the various grades available, contact us today.