For more than 40 years, McDonald Steel has been a premier provider of specialty hot-rolled steel components for railroads across North America. As demand for rail freight shipment continues to increase, track maintenance is critical to reliable and safe railway infrastructure.

McDonald Steel has the experience and facilities necessary to provide the highest quality specialized steel components in a range of sizes and configurations to meet even the most stringent industry requirements. Our dedicated team of engineers works directly with our customers’ engineers to custom design a product that meets their needs.

Contact Us

Standard Products for the Railroad Industry

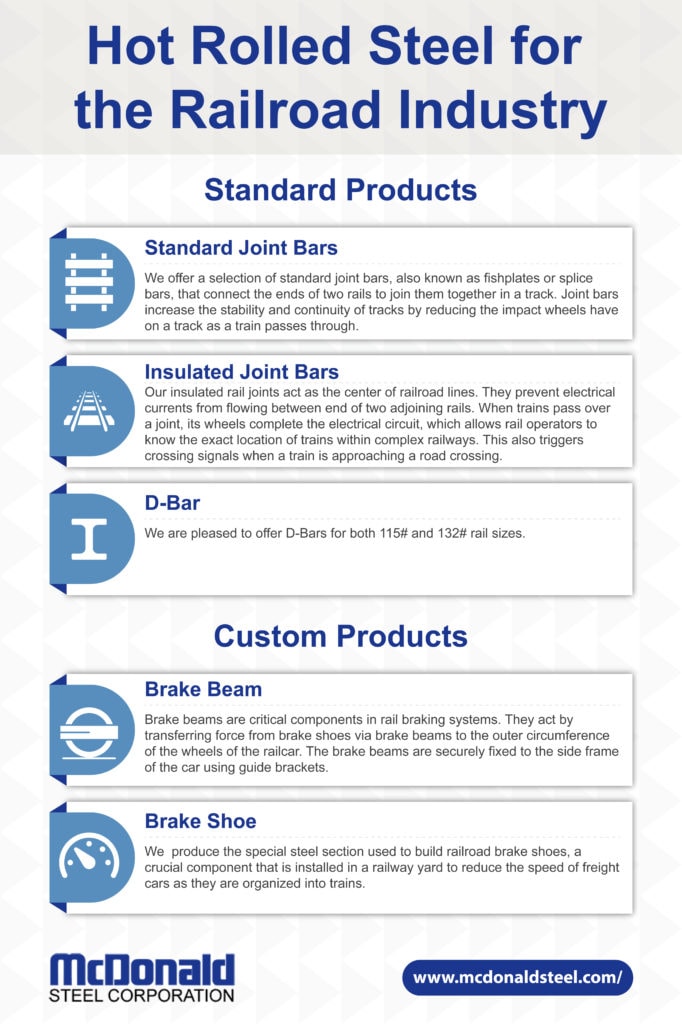

McDonald Steel is pleased to offer an extensive range of railroad steel shapes, including standard joint bars, insulated joint bars, and D-Bars. Our railroad steel products are designed for the utmost efficiency, safety, and reliability of your railway operations.

Standard Joint Bars

We offer a selection of standard joint bars, also known as fishplates or splice bars, that connect the ends of two rails to join them together in a track. Joint bars increase the stability and continuity of tracks by reducing the impact wheels have on a track as a train passes through.

Insulated Joint Bars

Our insulated rail joint bars act as the center of railroad lines. They prevent electrical currents from flowing between the ends of two adjoining rails. When trains pass over a joint, its wheels complete the electrical circuit, which allows rail operators to know the exact location of trains within complex railways. This also triggers crossing signals when a train is approaching a road crosssing.

D-Bar

We are pleased to offer D-Bars for both 115# and 132# rail sizes.

Custom Products for the Railroad Industry

In addition to our dependable and consistent joint bars, we offer custom designed steel components for a range of rail applications.

Brake Beam

Brake beams are critical components in rail braking systems. They act by transferring force from brake shoes via brake beams to the outer circumference of the wheels of the railcar. The brake beams are securely fixed to the side frame of the car using guide brackets. At McDonald Steel, we roll the hot rolled special shape steel profile which is then manufactured into brake beams to fit both new and existing equipment, even with unusual or complex geometries.

Brake Shoe

McDonald Steel also produces the special steel section used to build railroad brake shoes, a crucial component that is installed in a railway yard to reduce the speed of freight cars as they are organized into trains. Brake shoes are made up of a series of brakes that surround each rail section and create friction as a train rolls through, slowing a cars’ wheels by gripping them.

Important Factors to Consider for Railroad Products

Although it may seem that harder steel would be better, rail steel is actually slightly softer than hardened steel. The softer material enhances the material’s wear resistance and prevents cracks that are common in more brittle steel blends. Rather than cracking, rail steel will wear down to a new surface rather than cracking under the repeated strain of rail traffic.

Another important component in rail trackwork is the rail joint bar which is also referred to as a rail fishplate or splice bar. McDonald Steel utilizes a chemical composition in the microalloyed joint bars which adhere to AREMA (American Railway Engineering and Maintenance-of-Way Association) specifications. The exact chemical composition is agreed to by the purchaser and the manufacturer to achieve superior mechanical properties. The microalloyed joint bars are manufactured to meet or exceed AREMA specifications for both standard and high strength joint bars.

Superior Steel Solutions From McDonald Steel

At McDonald Steel, we are committed to providing quality manufactured steel shapes for an extensive range of applications and industries. Our state-of-the-art facilities include a walking hearth reheating furnace, roller bearing finishing stand, double rollers, and slitters that produce common rail components such as standard joint bars, insulated joint bars, and D-bars or custom hot rolled shapes. In fact, we are one of the few mills in the world that can produce customized and non-symmetrical metal shapes, such as brake shoes and brake beams. In addition, our hot rolled profiles offer an accurate, cost-effective alternative to forging, casting, extruding, and other complex fabrication and machining processes.

At McDonald Steel, we are committed to providing quality manufactured steel shapes for an extensive range of applications and industries. Our state-of-the-art facilities include a walking hearth reheating furnace, roller bearing finishing stand, double rollers, and slitters that produce common rail components such as standard joint bars, insulated joint bars, and D-bars or custom hot rolled shapes. In fact, we are one of the few mills in the world that can produce customized and non-symmetrical metal shapes, such as brake shoes and brake beams. In addition, our hot rolled profiles offer an accurate, cost-effective alternative to forging, casting, extruding, and other complex fabrication and machining processes.

Whether you need McDonald Steel to roll a mill lot quantity of hot rolled steel special shapes to manufacture your microalloy joint bars or saw cut to length feed stock to produce your railroad brake shoes, we have the knowledge, equipment, and expertise necessary to ensure that your rail components are designed and manufactured to meet the most stringent specifications. You can rely on us to create custom steel shapes that are accurate, consistent, and reliable, and our seasoned engineering team works directly with your engineers to design the perfect product for your needs.

To learn more about our railway steel solutions, contact our experts today.