All tooling is produced in house to ensure conformance to exacting specifications and is maintained by McDonald Steel.

McDonald Steel’s hot rolled special steel shapes are jointly developed with our customers to create a near net section that minimizes material waste and the need for machining. Tooling designs for hot rolled special steel shapes require precise calculations based on our customer’s final product specifications. Adjustments are made to the specifications to accommodate the mill’s rolling temperatures and the material’s metallurgical characteristics.

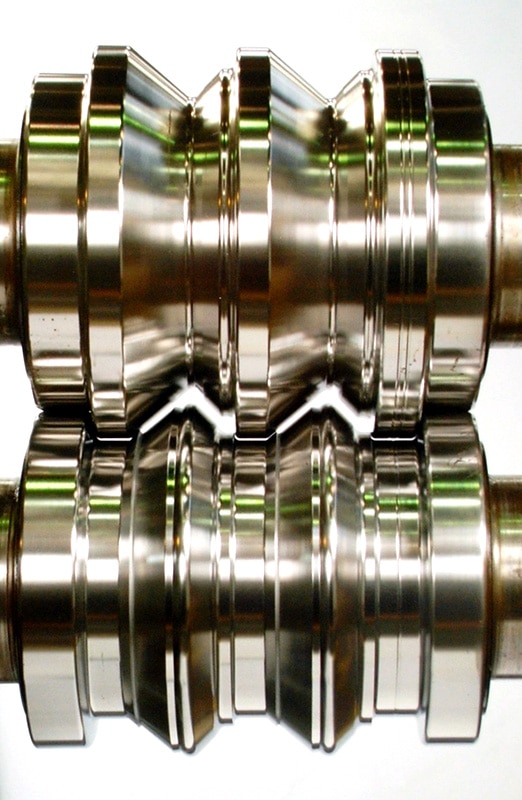

The custom development of our product-specific tooling is supported by CAD programs and direct numerically-controlled lathes. The customer’s hot rolled special steel shape travels through eleven sequential roll sets where the hot billet is formed into its final and often asymmetrical configuration. Hot rolled tooling consists of 22 rolls plus replacement rolls, roll guides, shear knives and if required, straightening rolls.

All McDonald Steel tooling is manufactured for proprietary use only by the customer for whom it was produced. After an initial tooling charge for each special steel shape, customers pay no more for the rehabilitation of worn tooling or replacement rolls for their existing sections.