Why Buy American Steel?

Although American steel has been on the decline over the last few decades, its reputation remains strong. Companies know they can rely on it, and in the wake of the pandemic and the associated supply chain challenges—not to mention the reshoring trend that started years ago and has accelerated during the pandemic—the American steel industry is poised to make a comeback.

Contact Us

How American Steel Benefits the Supply Chain

During the pandemic and in the aftermath of the ship stuck in the Suez Canal, companies who had long relied on cheap foreign steel found themselves in trouble. They faced delays and rising costs, including high tariffs on imported steel. Due to nation’s heavy reliance on cheaper foreign steel imports up until now, prices and availability of domestic steel have become more competitive. As more U.S. companies shift to a steel supplier closer to home, we should see positive growth in domestic manufacturing of quality steel, and as a result, American jobs.

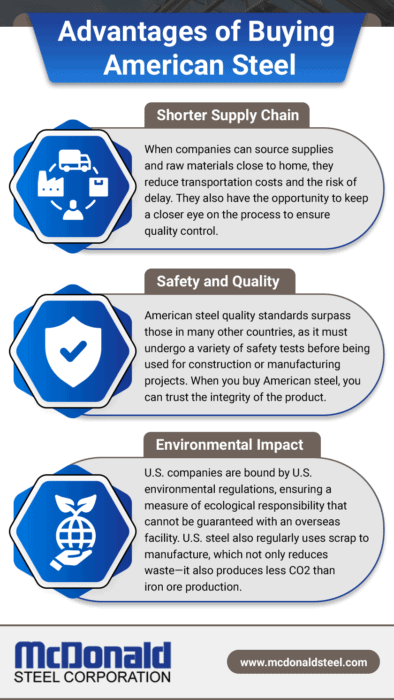

A shorter supply chain is always a benefit, and American steel is no exception. When companies can source supplies and raw materials close to home, they reduce transportation costs and the risk of delay. They also have the opportunity to keep a closer eye on the process to ensure quality control.

Advantages of Buying American Steel

Reduced transportation costs and better availability aren’t the only reasons to buy American steel. Why buy American? No matter the industry, it’s an opportunity to boost the national economy, support local communities, and take advantage of a skilled workforce. For steel in particular, there are further implications:

Safety and Quality

American steel is simply better. The quality standards in this country surpass those in many other countries, and steel must undergo a variety of safety tests before it can be used for construction or manufacturing projects. When you buy American steel, you can trust the integrity of the product.

Reporting from 2008 indicated that Chinese steel had a 60% failure rate in one series of tests and could pose a safety hazard for construction projects. This was largely due to the addition of chromium and boron, which were added to the steel to create an alloy that qualified for tax rebates. Some companies may have saved some money in that process, but it was at the cost of compromised steel.

Environmental Impact

U.S. companies are bound by U.S. environmental regulations, ensuring a measure of ecological responsibility that cannot be guaranteed with an overseas facility. American steel companies are also driven by consumer demand to look for other ways to lower emissions and enhance sustainability. U.S. steel also regularly uses scrap to manufacture steel, which not only reduces waste—it also produces less CO2 than iron ore production.

American steel has a long, rich history, and the integrity and reliability that was established years ago still remains. By replacing foreign steel with American steel, companies have the opportunity to bolster the U.S. economy, support their local communities, shorten their supply chains, improve quality control, decrease their environmental impact, and create higher-quality products for the end user. It’s a win-win situation that benefits businesses and consumers alike.

Working with McDonald Steel

McDonald Steel Corporation is a proud U.S. steel manufacturer based in McDonald, Ohio. We’ve grown from humble beginnings in 1981 into the country’s leading provider of highly engineered hot rolled steel special shapes for a variety of industries, including railroad, automotive, infrastructure, agriculture, construction, and more. Our commitment to innovation and community drives us to serve our employees and our customers with respect, integrity, and the high-quality products you expect and deserve.

Contact us to learn more about our facilities and capabilities, or to inquire about the benefits of using American steel.