McDonald Steel Partners with Customers

to Create Manufacturing Efficiencies

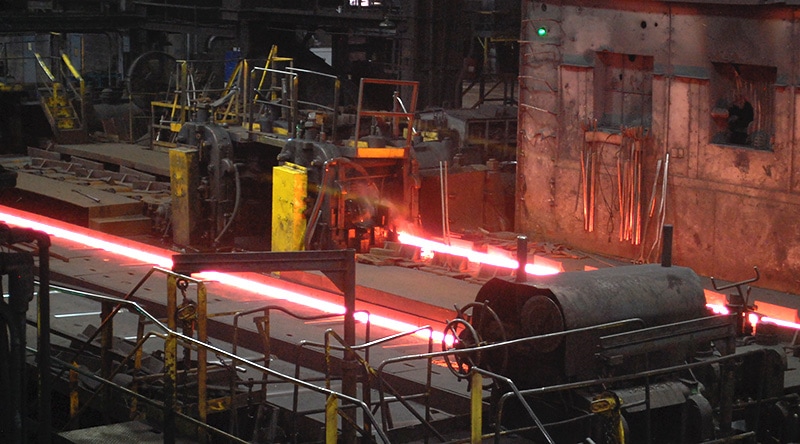

Production efficiencies offered by engineered hot rolled steel shapes provide manufacturing economies for a multitude of markets. Industry-leading manufacturers rely on McDonald Steel for the precision hot rolling technology and experience necessary to meet unique product requirements and improve production costs.

Manufacturing efficiencies are a primary concern in product development. McDonald Steel partners with customers to design cost-saving near net shapes that minimize material expense and maximize production efficiency. Our engineers work closely with manufacturers to develop unique roll designs that reduce or eliminate the production costs associated with subsequent machining. McDonald Steel hot rolled special steel sections are also an economical alternative to forgings, castings, extrusions, cold drawn and machined products.

Industries need reliable steel parts that keep performing day in and day out. Our special steel sections have a long history of adding quality and strength to products used in tough applications. McDonald Steel’s hot rolled shapes provide the rugged structural integrity required by the world’s leading automakers and infrastructure products companies. Our hot rolled special steel sections are engineered to meet or exceed the high standards established for critical products such as bridge decking, construction material and heavy equipment parts.

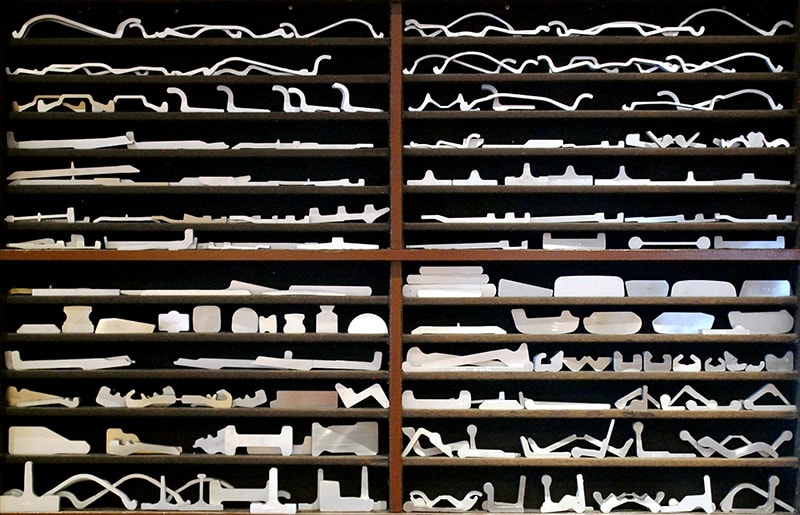

McDonald Steel is tooled to roll more than 500 asymmetrical and symmetrical hot rolled steel shapes. Our tooling is produced in-house to exacting specifications and continues to be serviced throughout its life cycle by McDonald Steel’s team of ISO 9001:2015 Certified professionals. We maintain the highest quality standards for section straightness. Every shipment is accompanied by Material Test Reports verifying the product’s specified mechanical properties and material composition. Please contact McDonald Steel at mscshapes@mcdonaldsteel.com for a cost-saving quotation.

• Customer Service

We pride ourselves on McDonald Steel’s responsiveness to anticipating and satisfying our customers’ needs.

• Operational Excellence

The McDonald Steel team partners with our customers to provide innovative, industry leading solutions.

• Quality Products

Our entire team is committed to meeting our customers’ exacting manufacturing specifications and delivering their product on time every time.

• Near Net Shape Product Development

The McDonald Steel design team partners with our customers to reduce or eliminate subsequent machining of their parts.

• Made in U.S.A.

McDonald Steel’s centrally located facility in northeast Ohio ensures expedited delivery of our American-made hot rolled steel profile shapes.

• ISO 9001:2015 Certification

McDonald Steel maintains in-house product design and engineering capabilities.

• Financial Strength and Flexibility

We are constantly reinvesting capital in the advanced technology that will ensure McDonald Steel remains a world class supplier for years to come.

• Indoor Storage

We offer ready-to-ship warehousing services for our customer’s hot rolled special steel shape inventory.